Die Casting Chillers

WPI can provide a wide range of chiller systems to meet your die casting process needs. Chiller systems available include modular chillers, packaged chillers, closed loop chiller systems, split chillers, once through cooling, portable chillers, glycol chillers, and custom cooling systems.

Application Description:

Die casting is the process of forcing molten metal under high pressure into mold cavities (which are machined into dies). Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminium, magnesium, lead, and tin based alloys, although ferrous metal die castings are possible. The die casting method is especially suited for applications where a large quantity of small to medium sized parts are needed with good detail, a fine surface quality and dimensional consistency.

This level of versatility has placed die castings among the highest volume products made in the metalworking industry.

In recent years, injection-molded plastic parts have replaced some die castings because they are cheaper and lighter. Plastic parts are a practical alternative if hardness is not required and little strength is needed.

Packaged Chillers Non-expandable (integrated pump tank) 1.5Ton – 20Ton Single / Dual Circuits Single / Dual Pumps |

SAE Series Modular Chillers Expandable (pump & tank on separate skid) 1.5Ton – 200Ton Single / Dual Circuits |

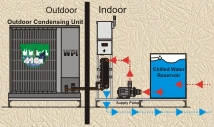

SAR Series Split Chillers Expandable (Outdoor Condensing Unit) (pump, tank, evaporator on indoor skid) 1.5Ton – 200Ton Single / Dual Circuits |